With so many moving parts and opportunities for paper jams, it's a wonder that many printers last as long as they do. Especially since, on average, support pros devote precious little time to working on printers. It's too bad, because costly repair bills can add up quickly, and replacing printers before their time is an expensive endeavor. While supporting printers is hardly glamorous, a little effort will lengthen any printer's lifespan. Use these tips for any type of printer you support. Just keep in mind that consulting the printer's owner's manual is always a good idea before embarking on any major printer maintenance procedure.

#1: Clean the inside of your printer

As simple as it may sound, one of the best preventive maintenance tasks you can perform is to keep your printer's insides as clean as possible. It's easy to do, if you look for excess paper dust or other debris whenever you open up your printer. At least once a month - or more often, if your users print a lot - use a can of compressed air to blow the dust and debris out of the printer.

#2: Refrain from using bent, torn, or used paper

Damaged paper can cause paper jams. Any time a paper jam occurs, there's a possibility that something else on the printer can break. To prevent jams and other problems, always use new paper that isn't bent, torn, or damaged in any way.

#3: Use high-quality paper

As a cost-saving measure, many organizations purchase medium- to low-grade paper to use in their printers. However, this type of paper can also cause paper jams. Although a decent brand of 20lb paper should suffice for most printing jobs, to make your printing shine, you should use at least 24lb paper. To help you determine exactly what type of paper you should use in your printer, most printer manufacturers publish minimum paper standards. If your paper doesn't meet these specifications, the vendor won't provide warranty support until you use the proper type of paper. Review the documentation that came with the printer or visit the manufacturer's Web site to learn the paper specifications.

#4: Store paper in a low-humidity environment

High environmental humidity can cause paper to stick together, leading to paper jams and paper feed errors. This is especially true for low-end printers or DeskJet printers, whose paper-feed mechanisms are not as finely tuned to separate pages in the paper tray. To prevent multiple pages from sticking together and feeding at the same time, store your paper in a cool, low-humidity environment and locate your printer in a low-humidity environment.

#5: Use high-quality labels

Whenever a printer is used for making labels, always supply it with high-quality label stock. This is even more important than using high-quality paper because cheap labels can completely ruin printer parts, such as a platen or fuser. When cheap labels are sent through a fuser or around a roller, they can peel off of the backing paper and become affixed to the first surface they come in contact with. This wreaks havoc with printer parts because you either have to peel the labels off, which can be an enormous task, or you're forced to replace the part. In the case of fusers, the cost of such a repair can be several hundred dollars. High-quality labels, on the other hand, do not come off quite so easily, so you can use them with less fear of damaging the printer.

#6: Use the straightest paper path for labels

When printing on label stock, eliminate as many bends in the paper path as possible. For example, use the manual feed tray, which allows the labels to feed directly into the printer without bending. If the printer has an additional paper exit path that eliminates the labels passing around another roller, you should use it. Reducing the number of rollers that label stock passes around will reduce the possibility of a label peeling off the backing paper and sticking to something inside of the printer.

#7: Replace old and worn rollers

Worn feed rollers are another cause of paper jams. When the rollers have come to the end of their useful life, they'll have a glazed and/or slippery surface that lets the paper slip off. This can either prevent the paper from being picked up in the paper tray or cause the paper to feed incorrectly while in the paper path. In laser printers, rollers normally have a life expectancy that is as long as the printer maintenance kit's. Therefore, if you change the rollers when you change the maintenance kit, you shouldn't have too many problems with feed rollers. However, DeskJet and other types of printers don't normally require a tune-up like laser printers do, so you won't need to change the feed rollers on a regular basis. Often, the manufacturer will offer a kit you can use to rough up the surface of a roller, so it will reliably pick up paper again. These kits include a very stiff Scotch-brite pad and a program that causes the feed roller to run against the pad so the surface of the roller is roughed up. If your printer's manufacturer doesn't offer such a kit, you can do the job yourself with a small file. If you do, be sure to rough up the roller surface evenly.

#8: Close the manual feed tray when not in use

If the printer uses a manual feed tray for printing labels or legal-size documents, make sure that it's always closed when not in use. A quick turn of a chair or an accidental slip could cause a user to bump into the protruding tray and break it. Although it may be a slight inconvenience to keep unfolding the tray, it's much safer in its stored position.

#9: Use care when replacing parts

Since printers are made of breakable materials like plastic, you should use care when assembling or repairing them. This is especially true when working with covers and cases because the small plastic tabs that hold them in place are easy to break off. If you find yourself exerting a great deal of force when reassembling a printer, you should probably back off and take another look at how the parts fit together. The chances are good that the angle you're using to put the parts together is wrong or the parts don't fit together the way you thought they did.

#10: Purchase a service manual

If you'd like to know more about repairing your particular model of printer, you can buy a service manual from the manufacturer. These manuals provide extensive troubleshooting tips, subassembly diagrams, and other useful repair information. When it comes time to make repairs on your printer, the service manual will make your job much easier. Depending on the type of repair you're doing, you may even be able to read step-by-step instructions for solving your particular problem.

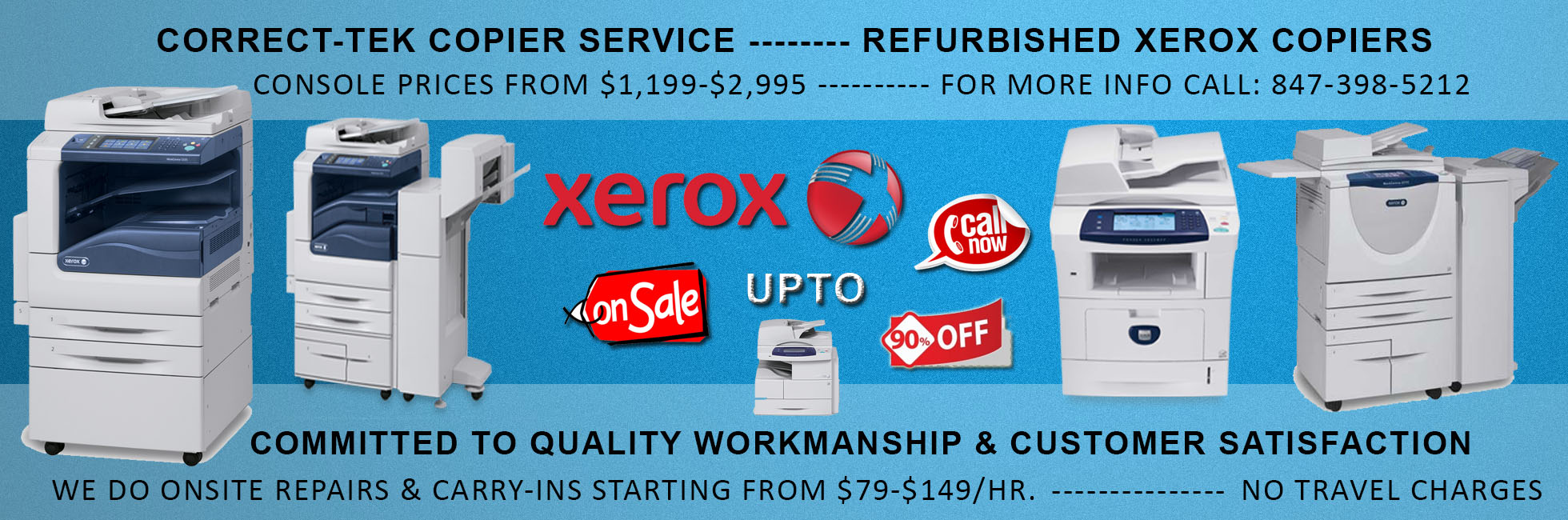

For more info - http://ctcopiers.blogspot.com/

No comments:

Post a Comment