So you need ten sets of a fifty page document for this

morning’s meeting. It's 8:30AM and your

meeting is at 9:00AM. You begin with

your project and the copier jams. You

clear the jam, but it keeps jamming! It's not pulling in the paper. Sure you can call the

copier repair person,

but you need the copies now! There's nothing you can do, or is there?

All office equipment that feeds paper has a component inside

that pulls the paper out of the paper tray and into the machine. Most are made out of rubber and just like the

tires on your car they wear out. When a roller is worn and dirty they will

cause paper jams. The purpose of this

article is to show you how you can clean or rejuvenate the rollers long enough

for you to complete your job and have your repair person come out and fix it

properly.

Alternative Solutions:

When your machine is jamming, first locate where the paper

is jamming. Which paper tray? Is it tray 1 or tray 2? Also which size paper is jamming? On machines that have more than one paper tray

you can switch paper trays and then you can skip cleaning the rollers. Make sure when you change cassettes that the

copier registers the correct paper size. The machine will think it is a different size

and it will jam. The sensors are set for

a specific timing, and it will know the difference in length from letter size

and legal size. I also would try using

the bypass tray or manual feed tray, if so equipped. This will get you up and running quicker than

cleaning the rollers.

Determining if the Rollers

are the Problem:

If you need the specific tray to be functional we will get

busy with the repair.

First make a single copy in the tray that is jamming. By doing this, you are determining where the

paper is jamming. If it is jamming in

the exit for instance, you have another problem. If it is jamming in the center of the machine,

again it is a different problem. Now if

it jams at the cassette or paper tray area, the next step is removing the paper

tray. Shine your flashlight into the

paper feed area, and see if there are any pieces of paper torn off inside or

something blocking the paper path. Now

that you have ruled out a blocked paper path, you can clean the feed roller(s).

Tools Required:

Flashlight, strong cotton towel (so it will not rip off in

the machine), WD-40 or Rubber roller rejuvenator.

Note: Never use alcohol to clean rollers. It dries out the tread and the remaining tread

will get ripped off and then it still will not feed. Use WD-40 it works great!

Cleaning the Rollers:

Shine your flashlights into the paper feed area and locate

the rubber rollers that feed the paper in. Grab your towel and saturate it with cleaning

fluid. This can be WD-40 or your

favorite roller rejuvenator. Start by cleaning the roller and spinning it all

the way around not missing any of the surfaces of the roller. Then go over it again with the dry part of the

towel. As I said, there are many

different types. Some have a set of three rollers. One Pre-feed roller, this pushes the paper

into the other rollers. One feed roller

and one separation roller. Others have a

half moon style. These are harder to

clean because they have a clutch system that keeps it at home position when not

feeding.

WARNING: If you

try and turn these to clean them you will damage the clutch mechanism! There are two ways you can clean these types. First you can actuate the clutch by pushing

down on the solenoid or release lever. This

sometimes can be hard to get to though. You

can also start the copy process and shut off the machine exactly when the feed

roller engages. This takes some patience

and practice, but it is better than damaging the clutch. Once you get it where you can clean the roller,

repeat the procedure above.

Some alternatives to

replacing feed rollers:

There is a material called feed roller tape. I have used it when I didn't have the right

roller in my car stock. It works with

some styles, mainly half moon styles. Just peel off the adhesive and wrap it around

the worn roller surface. They also have

some that stretch over the old rollers. On old

copiers or printers that you can no

longer get parts for, you can apply clear silicon on the feed surface and let

it dry twenty four hours. It works, but

I am inclined to use the real thing. You

can also use generic rollers manufactured for almost all equipment. I have mixed feelings about these, because I

have had to go back and change them again later. For the best repair, I use genuine OEM feed

rollers. They are still inexpensive and

they will last you longer, and you will have fewer headaches.

Feed Rollers

There are many types of rollers and feed systems. Rollers will normally come in a maintenance

kit but they may need to be replaced approximately half way through the

maintenance kit cycle.

I hope this has helped you complete your print or copy job. Please remember that, this article is just a

quick fix and not a long term solution. Be

sure and call your copier repair person to fix it correctly.

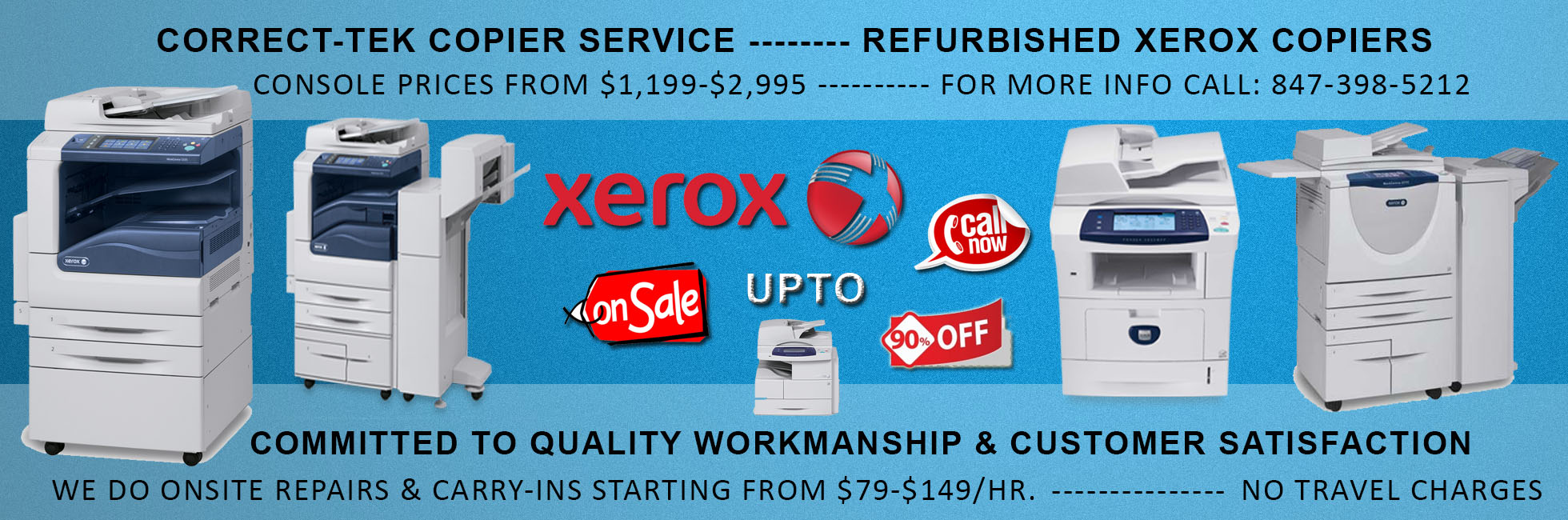

Check out our website at http://www.ctcopiers.com/ to make an informed choice.